Fold width 1150-1500mm DFL

Shuttle number 8pcs

Weft insertion (max.) 960ppm

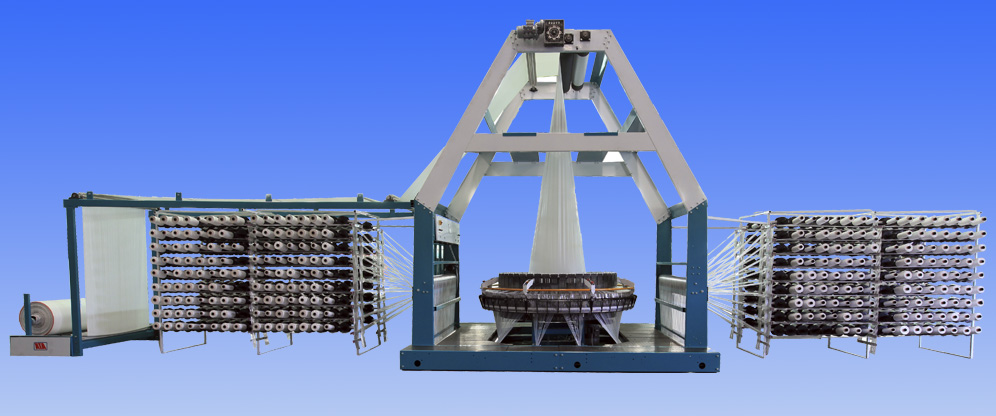

Qty Description

1 Main machine

l 24 sets of heddle belt + heddle wire, 22 of heddle wires stations in each group, totaling 528 pcs.

l Rolling reed structure is beneficial to the oil-free fabric, enhances the film coating effect, and meets the requirements of food-grade products.

l The main motor Siemens variable frequency drive.

l With automatic refueling cup, you can set the refueling time and fueling amount on the control screen.

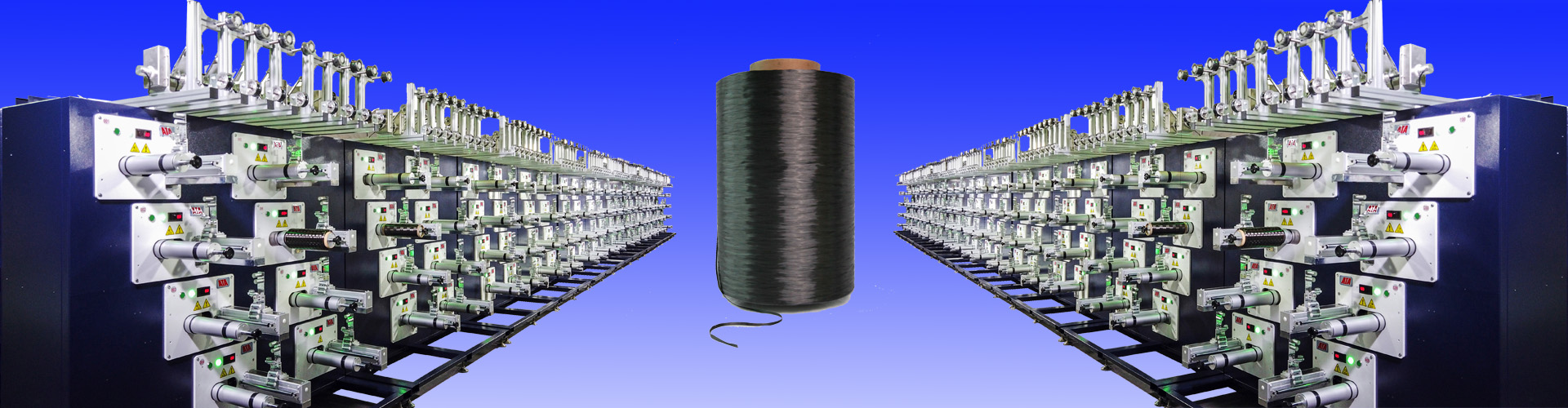

4 Shuttle

l The shuttle is equipped with an automatic weft yarn tension control device.

l The shuttle is equipped with front and back Block yarn plate, Max.can loading 110mm diameters weft yarn.

1 Circular loom control system

Circular loom central computer control system can be used

? Adjust the weft density

? Set the length of the Fabric

? Order order

? Manually operate the lifting system without turning it on and provide the following device parameter indications:

l 4 file automatic meter

l Run time calculation

l Change roll / cloth roll indication

? Equipment Evaluation System

The module determines the following additional parameters for each class and evaluates:

l Running time of the device

l The number of warp yarn breaks

l Number of weft yarn breaks

l Frequency of weft yarn use up

l The weft yarn can be precisely adjusted in the open/stop state to optimize the fabric surface effect.

l The above instructions are available in two languages (English/Chinese), with metric or imperial (inch) systems

2 Creel

l 2 creels total 512 stations

l The creel is designed according to the warp yarn spindle and can be loaded with a spindle with a diameter of 160mm.

Note: Not include Bobbin

1 Electrical configuration

? Lighting device

l Equipment is equipped with 2 sets of 18W LED lighting tubes

? Heat sink

l Not Equipped cooling fan in Tension frame.

l But the fan interface and switch are reserved in the control cabinet.

? Let-off system

l A total of 2 feed rollers, ensure that the warp yarns are smoothly fed into the main machine and maintain the real-time tension average.

l Each let-off motor is controlled by load cell + Inverter control let-off motor. Let-off roller control by Let-off motor.

? Take-up system

l Weft density is set by the circular loom main control system.

l Take-up motor 0.37 KW power driven by a frequency converter.

? Central drive system

l Through the V belt by three-phase inverter control motor (two-stage transmission) driven CAM rotation control over and drive the shuttle.

l Main motor power is 2.2 KW

? Weft yarn detection

l It is equipped with a photoelectric sensor and a proximity switch to control the weft yarn together and stop automatically when the weft yarn used up.

l It is recommended to use black bobbin for best effect.

Remarks: Please use light colored tube for black yarn!

? Warp yarn break detection system

l Each warp yarn is length compensated by tension adjuster and automatically stops the machine when yarn breaks.

l The warp yarn breakage has an indicator light, and the 4 groups of indicator lights are distributed around the equipment.

? Weft yarn break detection system

l 1 sets of magnetic sensors monitor the weft yarn. In case of broken weft yarn, it will stop the machine automatically.

? Button boxes

l There are 4 sets of button boxes around the main machine for easy operation. Each control box have inching button, stop buttons and start buttons; all are Schneider brand.

1 Fabric winding device

l A friction type winding device is equipped with a load cell, which is controlled by a 0.37KW inverter, and the winding motor is a 1.8NM torque motor.

l We offer a 3″ roll core (standard size).

Remarks: 4".6" roll core can be selected - need to be customize

1 Bobbin saving

There is a platform on each side of the circular loom for placing the bobbin.

* according to equipment requirements

We reserve the right to modify the technical parameters due to the continuous improvement of equipment technology.

| Shuttle/ machine | 8pcs |

| Weft insertion (max.) * | 960ppm |

| Working width | 1150 – 1550mm |

| Weft density | 20 – 40 /10 cm |

| No. of warp tapes | 1152pcs |

| Bobbin inside diameter ** | 38mm |

| length of bobbin ** | 220mm |

| Warp bobbin diameter(Max.) | 160mm |

| Weft bobbin diameter(max.) | 110mm |

| Winding roll diameter(Max.) | 1200mm |

** Please specify if there is any special requirements

HOME

HOME